Berries freezing features

It is possible to attract a consumer and make him a regular customer only if high quality is consistent, as well as refusal to use stabilizers and conservatives. How properly cool and freeze berries, and other products of a wide consumer spectrum - we will tell you in this review.

Find out more:

- Berries shock freezing chambers

- Quick berries freeze - practical tips

- The price of berries shock freeze equipment

- How to order berries shock freeze equipment

- Installation of berries shock freezing chambers

The cooling time and the freezing time affect different processes related to the quality of the product, semi-prepped product or finished meal. Quick freezing of berries does not give the formation of bacterial colonies a chance for in fresh berries and stabilizes the number of microorganisms that originally exist in the biological environment.

However, preserving the appearance, taste, and healthy properties of berries, fruits, and other products is not the only advantage of shock freezing. Direct economic effect also achieved due to:

- Reduction of preparation for storage;

- A significant increase in the allowable implementation period;

- Decrease in percent of shrinkage (freezing).

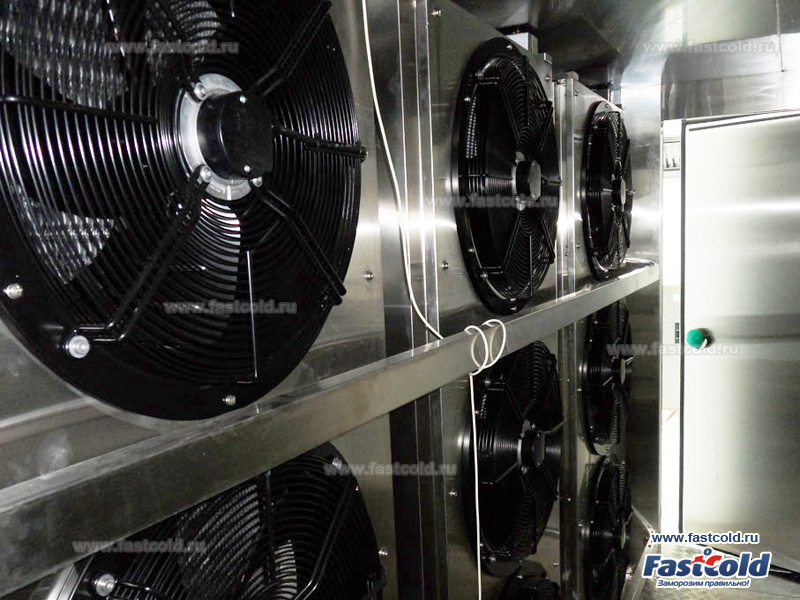

In practice, acceleration of cooling and freezing achieved by the lowest possible temperatures of the cooling medium and powerful convection (by mixing the layers of air in contact with the product). For this, it is envisaged to blow the object with the help of special fans.

Berries shock freezing chambers

Professional equipment provides not just accelerated freezing, but also a strict schedule of the process that is most suitable for a certain type of product.

We offer the following shock freezing equipment:

- Shock freezing chambers of a commercial series. Productivity: 65 - 300 kg/h (suitable for catering, catering, small food production);

- Shock freezing chambers of an industrial series. Productivity: 220 - 660 kg/h (intended for large food production, grocery hypermarkets).

Product loading performed using trolleys for baking sheets or gastronome containers. It is possible to use a tunnel type system (the possibility of through movement - the doors are located on the front and rear walls of the unit). You can see and select a model for the necessary task in the section "Shock freezing chambers"

Quick berries freeze - practical tips

1. Quality of raw ingredients

Quality understood as the integrity of berries, their taste, freshness; lack of bruising, mold, dirt; minimum content of leaves, twigs, and stalks.

2. Preparation of raw ingredients for freezing

Preparation of raw ingredients for freezing depends on the type of fruit:

- Berries to collect, sort out, clear from pollution and low-quality raw ingredients.

- Additional wash (except raspberries and strawberries), dry in the open air, preferably in one layer on a fine grid or on a perforated tray.

- Place the raw ingredients on a baking sheet with a sheet of dry parchment - especially for strawberries, raspberries, strawberries, as well as wild berries.

The packaging of berries before freezing should not be bulky; otherwise, the berries located in the center may not be freeze.

3. Berry freezing

The temperature and speed of fruit freezing affected by the degree of fruit ripeness, the duration and number of post-harvest operations.

Berries are a delicate product, so the choice of equipment should be very thorough. We recommend a specialized range of equipment for delicate products.

The evaporator and compressor are included in three stages, first the capacity is 30%, then 60% and only at the final stage 100%. Such a stepwise inclusion gives a gradual penetration of cold while maintaining the cooling rate and freezing.

4. Rules for storage of berries

- The most favorable storage carried out at a temperature not higher than -18°C and not lower than -25°C, the relative humidity in the storage chamber should be 90-95%.

- During the entire period of storage of berries, their thawing is strictly not allowed.

5. Defrosting berries

To obtain a quality product after defrosting, we recommend defrosting berries at a temperature of +2°C +4°C for at least 12 hours. On the other hand, in a specialized defrosting cabinet.

The price of berries shock freezing equipment

The cost of chambers directly depends on several parameters - unit performance, capacity, and the availability of additional options. In order to find out the exact cost, select the necessary options and get expert advice, contact us by phone: + 7 (499) 112-32-04 or leave a request on the site.

How to order equipment for berries shock freezing

First, you need to decide on the main technological parameters of freezing necessary in production. These include:

- Produce type ;

- Loading type ;

- Input parameters (temperature, humidity);

- Necessary parameters of freezing (temperature, speed);

- Productivity;

- Architectural reference (space dimensions for the future chamber).

Based on this information, our experts draw up a preliminary equipment project, and prepare a quote on its basis. After being acquainted with the quote, all the necessary approvals are carried out, after which you can proceed to signing the contract. Once the contract signed, we proceed with manufacturing, delivery, and installation of the shock-freezing chamber at your facility.

Installation of berries shock freezing chambers

As practice shows, attempts independently commission complex refrigeration equipment do not result anything good. Despite the fact that all the necessary parameters taken into account during the design, real actual operating conditions require fine-tuning of the operation of the main units. Errors in this work lead to a violation of the freezing technology, which threatens with a loss of product quality, as well as unreasonable energy overrun during operation.

Our company has a staff of qualified installers specializing in the commissioning of refrigeration, freezing and climatic equipment. We believe that the key to effective work is the combination of three key stages: design, manufacture, and installation. If you work with us, you will receive high-quality shock freezing of products and guarantee long-term equipment uptime.