Design and principle of operation of refrigeration units for shock freezing

Learn more:

- Modular equipment

- Intensive airflow

- Internal structure and type of construction

- Alternative technology

In the chambers of high-speed freezing, as in the refrigeration equipment of the traditional type, mainly used compression-evaporation cooling technology. Sometimes the term "heat pump"is used to refer to it. Due to what shock freezing units demonstrate an order of magnitude greater intensity of the process? First of all, it:

- application of the modular schemes of complete set allowing to build in components of necessary rated power lines;

- ensuring compulsory blowing of products with cold air with excessive pressure from 50 to 100 Pas and above;

- the organization of internal structure of cameras considering free access of stream to all cooled elements.

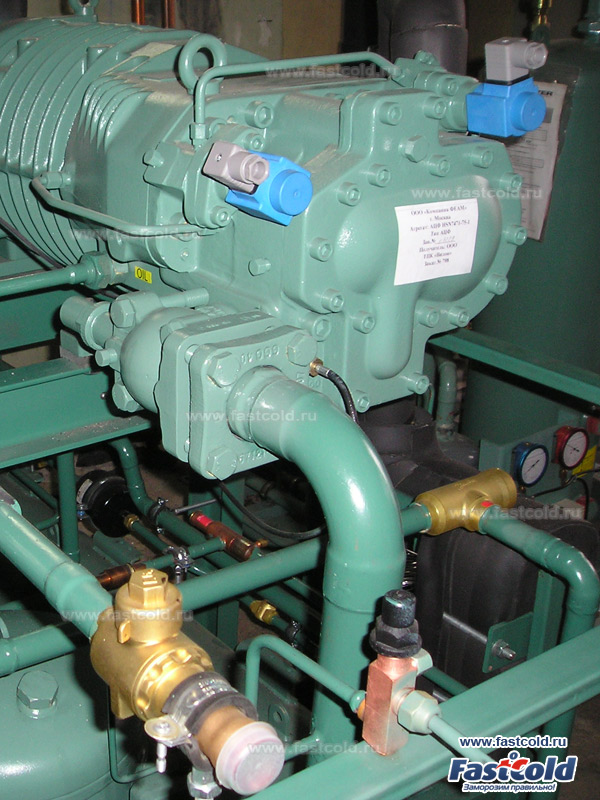

Modular equipment

Cooling occurs due to evaporation of the working fluid (refrigerant) in the evaporation line at low pressure. The refrigerant in the gaseous state enters the compressor, from where it is thrown at high pressure into the condenser line. In the condensation part of the installation, the working fluid is transferred from gaseous to liquid with heat transfer to the atmosphere directly or through water radiators. The liquid refrigerant enters the evaporator through the choke chamber (expander), closing the operating cycle. Shock freezing systems of compression type are designed and manufactured on the basis of ready unified units and machines that provide separate stages of the cooling cycle.

Plants and lines include:

- The compressors providing the difference of pressure between the evaporator and the condenser.

- Evaporators. The majority of modern industrial evaporators are completed with the integral fans. In such equipment they are called air coolers. Separate installations are projected especially for work as a part of devices of shock freezing and have the corresponding names with the Blast or Flash indexes.

- Condensers. Are made in the form of radiator stands, or in the form of cylinders or tanks. The last are, as a rule, intended for work with water-cooling towers (coolers) executed in the form of additional devices.

- Fans. Are used for equipment of air coolers, or for separate placement in cameras.

- Transport mechanisms. Linear and spiral machines are used. Pipelines of linear type are installed in tunnel units of shock freezing.

Compressors, evaporators and condensers are connected by pipelines in a single system, which circulates the refrigerant, which can be used as ammonia, freon, carbon dioxide and other gases with a boiling point not higher than - 20 °C (at atmospheric pressure). As a rule, each unit of the industrial evaporation scheme is able to work with different types of refrigerants.

Intensive airflow

The creation of a significant overpressure by the fans must correspond to the cooling capacity of the evaporator. In air coolers for shock freezing systems, the area of the discharge pipes is usually close to the area of the evaporating coils (radiators). In most of the chambers of the box type, cubic air coolers are installed. These devices are visually similar to the external units of air conditioners. They can be performed with a vertical or horizontal flow direction. Models with horizontal action of fans are mainly used.

The boxed shock freezing unit of one-sided loading, as a rule, is equipped with a set of several air coolers, occupying the entire area of the inner surface of the rear or side wall. This ensures a powerful and uniform cooling of products located on all shelves of the loading cart.

In end-to-end loading chambers and linear (tunnel) units, air coolers are usually located on one or two side walls.

Internal structure and type of construction

To ensure free access of cold air in the boxes, it is enough to Orient the flow parallel to the plane of the shelves. In the tunnel chambers, evaporators with or without fans (depending on the design of the installation) are placed along the entire section of the conveyor located within the thermally insulating casing.

Spiral installations require more complex technical solutions. In particular, the separate location of the evaporators and the fan network is used. Connection to a single system is carried out using metal ducts or special woven sleeves.

Alternative technology

Shock freezing systems that use a cryogen (nitrogen or helium) rather than a refrigerant are called cryogenic shock freezers. In contrast to the compression-evaporation scheme, these devices use open evaporation of the liquid working fluid into the atmosphere. In some cases, this technology is economically feasible, but has not yet been widely adopted. Another principle of high-speed freezing worthy of mention is contact high-speed freezing, in which the evaporator plates are pressed against the product, providing direct heat transfer.

Contact us and we will answer all your questions!

More comfortable writing?

We are waiting for your emails from@fastcold.ru

Want to talk?

Our phone + 7 (499) 112-32-04 always available for You!

Love coffee and personal communication?

We will always be glad to see You in our office at: g. ZHeleznodorozhnyj, ul. Keramicheskaya, d.3.